Understanding the Impact of Industrial Freeze Dryer Machines

Industrial freeze dryer machines, also known as lyophilizers, play a critical role in the modern refrigeration equipment landscape. These sophisticated machines are essential for preserving a wide range of products by removing moisture without compromising the quality or integrity of the materials. In this article, we will delve into the intricacies of industrial freeze dryer machines, exploring their features, benefits, applications, and much more.

What is an Industrial Freeze Dryer Machine?

An industrial freeze dryer machine is a specialized device designed to remove moisture from perishable goods through a process called freeze-drying. This process involves freezing the product and then reducing the surrounding pressure, allowing the frozen water in the product to sublimate directly from the solid phase to the vapor phase. This unique method preserves the substrate's structural and nutritional integrity, making it ideal for a variety of applications.

How Does Freeze Drying Work?

The operational process of freeze drying is comprised of three main stages:

- Freezing: The product is rapidly frozen to temperatures typically between -40°F and -60°F (-40°C to -51°C).

- Sublimation: Under controlled vacuum conditions, the temperature is raised slightly, causing the ice to sublime and converting it directly into vapor.

- Desorption: The remaining moisture is removed further by progressively raising the temperature under vacuum, ensuring that the product is completely dry.

Advantages of Using Industrial Freeze Dryer Machines

Industrial freeze dryer machines offer numerous benefits that make them indispensable in various industries:

- Preservation of Nutritional Value: Freeze drying retains the original nutrients and flavors of food products, making them a healthier choice for consumers.

- Extended Shelf Life: Products subjected to freeze drying can last for years without refrigeration, dramatically lowering food waste.

- Lightweight and Compact: The removal of water reduces the weight and volume of products, making storage and transportation easier and cost-effective.

- Retained Structure: Freeze-dried items maintain their shape, color, and texture, enhancing their appeal when rehydrated.

- Versatility: These machines can freeze dry an extensive variety of products, from fruits and vegetables to pharmaceuticals and biological materials.

Applications of Industrial Freeze Dryer Machines

The versatility of industrial freeze dryer machines allows them to be utilized in a myriad of sectors:

Food Industry

In the food industry, freeze drying is pivotal. It enables the long-term preservation of fruits, vegetables, meats, and ready-to-eat meals without the use of preservatives. This method also locks in flavors, ensuring that rehydrated food retains its taste and nutritional benefits.

Pharmaceuticals

The pharmaceutical industry benefits tremendously from industrial freeze dryer machines by providing a reliable method for preserving delicate vaccines, antibiotics, and other medications that demand strict temperature controls. This form of drying helps in maintaining the efficacy and stability of drugs, extending their shelf life significantly.

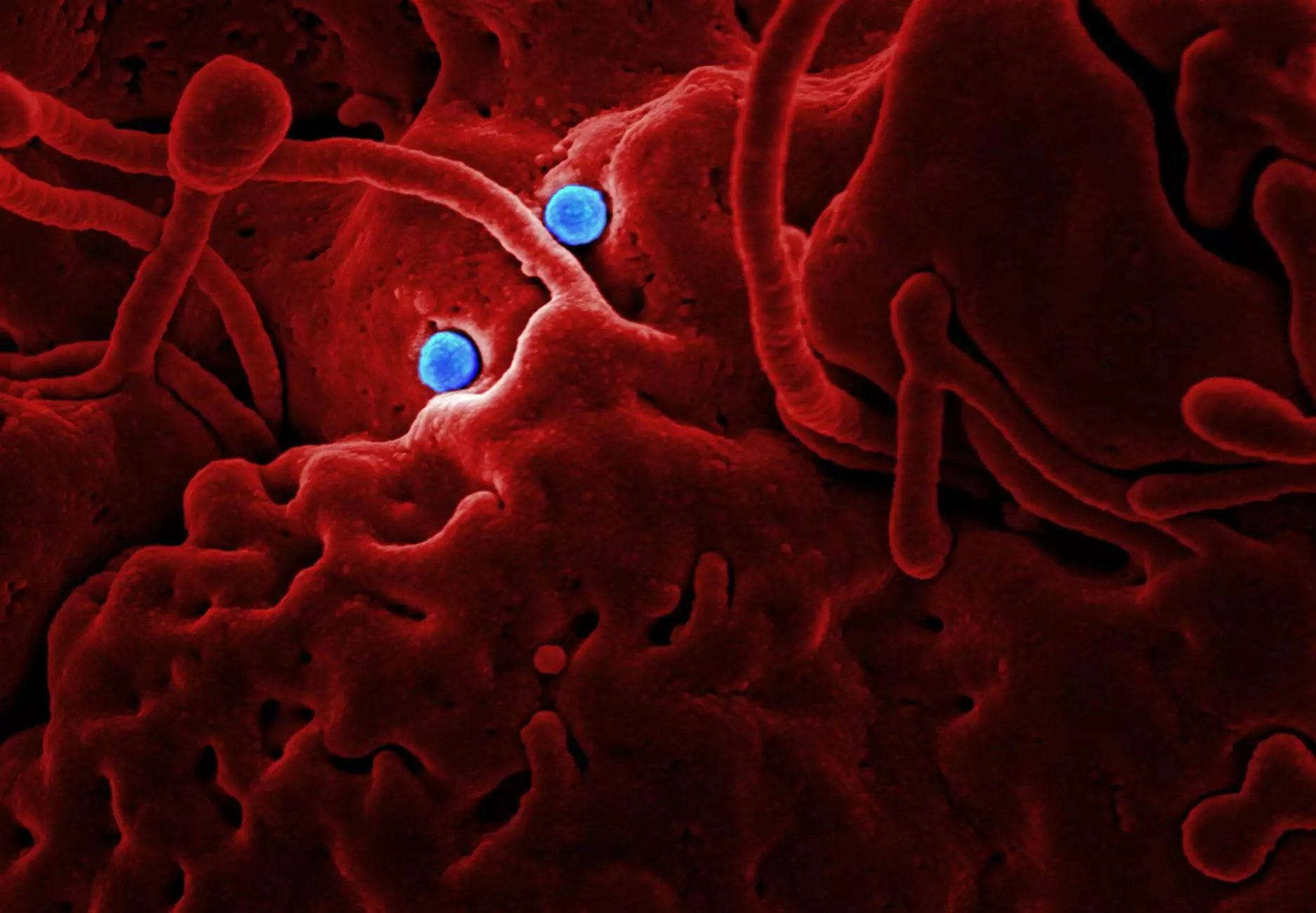

Biological Samples

Scientific research relies on the preservation of biological materials, such as proteins, vaccines, and other sensitive compounds. Freeze drying allows these samples to be stored efficiently for long periods, ensuring their viability for future studies.

Cosmetics

The cosmetic industry uses freeze drying to enhance the shelf life of products while maintaining the integrity of their active ingredients, providing consumers with high-quality skincare and beauty products.

Choosing the Right Industrial Freeze Dryer Machine

When selecting an industrial freeze dryer machine, several factors should be considered:

- Capacity: Assess the volume of products you will be freeze drying to determine the capacity needed.

- Energy Efficiency: Look for machines that consume less energy to reduce operational costs.

- Ease of Use: Consider user-friendly interfaces and controls that simplify the operation and monitoring of the machine.

- Maintenance Requirements: Evaluate the maintenance needs and costs associated with the machine to ensure longevity and performance.

- After-sales Support: Choose a supplier that offers comprehensive support and servicing for your freeze dryer machine.

Challenges Faced by Industrial Freeze Dryer Machines

While industrial freeze dryer machines present many advantages, they also come with challenges:

- High Initial Investment: The upfront cost of purchasing a freeze dryer can be significant, which may deter small businesses.

- Time-consuming Process: Freeze drying is a slower process compared to traditional drying methods, which might impact on-demand production.

- Specialized Training: Operators may require specialized training to ensure the effective use of freeze dryers, adding to operational costs.

Future Trends in Industrial Freeze Drying

The future of industrial freeze dryers is set to be shaped by innovation and technological advancement. Some trends to look out for include:

- Smart Technology Integration: The incorporation of IoT (Internet of Things) technologies will enable real-time monitoring and management of freeze-drying processes.

- Eco-friendly Solutions: Emerging machines are being designed with sustainability in mind to minimize environmental impact.

- Customization and Scalability: As the demand for tailored solutions grows, manufacturers are expected to develop customizable freeze drying options to accommodate different industries and product types.

Conclusion

In conclusion, industrial freeze dryer machines represent a significant technological advancement in the field of refrigeration equipment. Their ability to preserve products while maintaining integrity and nutritional value makes them invaluable in various sectors, including food, pharmaceuticals, and beyond. The growing demand for high-quality preserved products will continue to drive innovation, making freeze-drying technology an exciting area to watch in the coming years.

For businesses looking to invest in industrial freeze dryer machines, understanding their benefits and applications is essential to making informed decisions. With the right equipment and knowledge, companies can enhance product quality, reduce waste, and ultimately gain a competitive edge in the market.

Explore the range of options available at first-coldchain.com to find the perfect fit for your industrial freeze dryer needs. Embrace the future of refrigeration technology today!